Artificial Intelligence (AI) has been making significant strides in various industries, and logistics is no exception. AI has the potential to revolutionize the way businesses manage their supply chains, warehouse operations, transportation, and inventory management.

By leveraging AI technologies such as machine learning, natural language processing, and robotics, logistics companies can streamline their operations, improve efficiency, and reduce costs. In this article, we will explore the impact of AI on supply chain management, warehouse operations, transportation, and inventory management, as well as the challenges and limitations of AI in logistics.

Table of Contents:

- The Impact of AI on Supply Chain Management

- AI Applications in Warehouse Operations

- AI in Transportation and Route Optimization

- AI in Inventory Management and Demand Forecasting

- Challenges and Limitations of AI in Logistics

- The Future of AI in Logistics

- FAQ's

The Impact of AI on Supply Chain Management

AI has the potential to transform supply chain management by enabling real-time visibility, predictive analytics, and autonomous decision-making. With AI-powered tools, businesses can gain insights into their supply chain operations, identify potential bottlenecks, and proactively address issues before they escalate. AI can also help businesses optimize their inventory levels, reduce stockouts, and improve demand forecasting accuracy.

On the other hand, AI can also pose challenges in supply chain management, such as data privacy concerns, integration with existing systems, and the need for skilled personnel to manage AI technologies. Despite these challenges, the potential benefits of AI in supply chain management are too significant to ignore. As AI continues to evolve, businesses that embrace AI-powered supply chain solutions will gain a competitive edge in the market.

AI Applications in Warehouse Operations

AI is revolutionizing warehouse operations by enabling automation, optimization, and predictive maintenance. With AI-powered robotics and automation systems, warehouses can streamline their picking, packing, and shipping processes, reducing labor costs and improving efficiency. AI can also optimize warehouse layout and storage space utilization, leading to faster order fulfillment and reduced operational costs.

Furthermore, AI can enable predictive maintenance of warehouse equipment, reducing downtime and maintenance costs. Overall, AI is transforming warehouse operations by making them more efficient, cost-effective, and responsive to customer demands.

However, implementing AI in warehouse operations comes with its own set of challenges. Businesses need to invest in AI technologies, retrain their workforce, and ensure seamless integration with existing warehouse management systems. Additionally, there are concerns about job displacement due to automation.

Despite these challenges, the potential benefits of AI in warehouse operations are too significant to ignore. As AI continues to advance, warehouses that embrace AI technologies will be better positioned to meet the demands of an increasingly competitive market.

AI in Transportation and Route Optimization

AI is revolutionizing transportation and route optimization by enabling real-time tracking, predictive analytics, and autonomous decision-making. With AI-powered tools, businesses can optimize their transportation routes, reduce fuel consumption, and minimize delivery times.

AI can also enable real-time tracking of shipments, allowing businesses to proactively address delays and disruptions. Moreover, AI can help businesses optimize their fleet management by predicting maintenance needs and optimizing driver schedules.

AI in Inventory Management and Demand Forecasting

AI is revolutionizing inventory management and demand forecasting by enabling real-time visibility, predictive analytics, and autonomous decision-making. With AI-powered tools, businesses can optimize their inventory levels, reduce stockouts, and improve demand forecasting accuracy.

AI can also enable real-time tracking of inventory levels and demand patterns, allowing businesses to proactively address fluctuations in demand. Furthermore, AI can help businesses automate routine tasks such as order processing and invoicing, freeing up human resources to focus on more strategic activities. Overall, AI is transforming inventory management and demand forecasting by making it more agile, responsive, and cost-effective.

Challenges and Limitations of AI in Logistics

While the potential benefits of AI in logistics are significant, there are also challenges and limitations that need to be addressed. One of the main challenges is the need for significant investment in AI technologies and infrastructure. Implementing AI-powered solutions requires a substantial upfront investment in hardware, software, and training. Additionally, businesses need to ensure seamless integration with existing systems and processes to maximize the benefits of AI in logistics.

Another challenge is the need for skilled personnel to manage AI technologies. Businesses need to invest in training their workforce to effectively use and manage AI-powered solutions. Furthermore, there are concerns about job displacement due to automation in logistics. As businesses adopt AI-powered solutions for tasks such as warehouse operations and transportation management, there is a risk of job displacement for workers who perform these tasks manually.

Data privacy and security are also significant concerns when it comes to implementing AI in logistics. Businesses need to ensure that sensitive data such as customer information and supply chain data is protected from unauthorized access or misuse. Additionally, there are concerns about the ethical implications of using AI for decision-making in logistics. Businesses need to ensure that their use of AI technologies complies with ethical standards and regulations.

The Future of AI in Logistics

Despite the challenges and limitations of implementing AI in logistics, the future looks promising for businesses that embrace AI-powered solutions. As technology continues to advance, the capabilities of AI in logistics will only continue to grow. Businesses that invest in AI technologies now will be better positioned to meet the demands of an increasingly competitive market.

In the future, we can expect to see even more advanced applications of AI in logistics. For example, autonomous vehicles powered by AI could revolutionize transportation and delivery operations by enabling fully autonomous delivery fleets. Additionally, advancements in robotics and automation powered by AI could further streamline warehouse operations by enabling fully autonomous picking and packing processes.

Additionally, we can expect to see even more advanced applications of predictive analytics powered by AI in inventory management and demand forecasting. Businesses will be able to proactively address fluctuations in demand by leveraging real-time insights into customer behavior and market trends.

In conclusion, the impact of AI on logistics is significant and far-reaching. From supply chain management to warehouse operations to transportation and route optimization to inventory management and demand forecasting, AI has the potential to revolutionize every aspect of logistics!

FAQs

What are some common applications of AI in logistics?

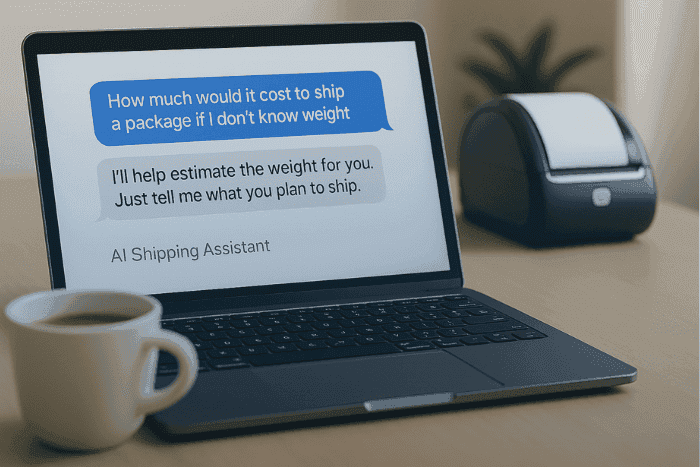

AI is commonly used for demand forecasting, route optimization, inventory management, predictive maintenance, and automating customer service through chatbots.

How does AI improve supply chain visibility?

AI enhances supply chain visibility by analyzing vast amounts of data from various sources in real-time, allowing companies to track shipments, monitor inventory levels, and predict potential disruptions.

Can small businesses benefit from AI in logistics?

Absolutely! Small businesses can leverage AI tools tailored to their needs to streamline operations, reduce costs, and improve customer experiences without requiring significant upfront investments.

What challenges might companies face when integrating AI into logistics?

Challenges include data quality issues, resistance to change within the organization, high initial costs of implementation, and the need for skilled personnel to manage AI systems.

Is AI in logistics only about automation?

While automation is a significant aspect of AI in logistics, it also encompasses advanced analytics, machine learning for predictive insights, and enhanced decision-making capabilities that go beyond simple task automation. By understanding these benefits and addressing potential challenges head-on, businesses can effectively harness the power of AI to revolutionize their logistics operations.